Platinum Palladium

The platinotype (a print made solely of platinum metal salts) was first patented by William Willis in 1873 for the Platinotype Company. They manufactured a large variety of photographic platinum papers as did their competitors Eastman Kodak and Gevaert. It was practiced widely until platinum became too difficult and expensive to source when the British government restricted its use to the production of explosives during World War I. The cheaper and easier to obtain palladium was introduced into the emulsion at this time. After the war, cameras became smaller, producing negatives unsuited for the contact printing done with platinum printing. The process fell into obscurity but resurged in the 1960s as alternative processes gained popularity.*

Platinum Palladium Workshops

They are often called the holy grail of photographic printing.

Why?

Wide Tonal Range

Between black and white there are endless shades of smooth and nuanced greys. The tonal range opens the shadows of an image and expands the highlights so that more detail can be seen in these extreme parts of the image.

Precious Metals

The print is made up of a chemical mixture of the precious metals platinum and palladium, hence the name.

Fade-Resistant

Photographic media is by definition light-sensitive, and platinum palladium is the most permanent and fade-resistant of them. Platinum and palladium are noble metals meaning they are resistant to corrosion and oxidation, common problems with silver and pigment prints. The paper the image sits on will disintegrate before the image changes.

*For more information on the history of platinum palladium printing and the print itself read The Atlas of Analytical Signatures of Photographic Processes: Platinotype by Dusan C. Stulik and Art Kaplan.

Luminaria’s Capabilities

David Hyams, master printer and our co-founder, has spent his career understanding the chemistry behind these prints, how to control variations, and using digital negatives for consistency, ease, and preventing waste. Some of our capabilities include:

Controlling tonal shifts

Would you like your print to be warmer, cooler, or somewhere in between? We can print to your desired aesthetic.

Glossy finishing

Platinum palladium prints have a matte surface. We can add a glossy finish with a final coat of gum arabic, enhancing contrast.

Digital Negatives

Platinum palladium requires contact printing, meaning the negative is not enlarged but printed 1:1 on the paper. With calibrated digital negatives we can take any of your digital images and output the perfect negative for your final print. Print sizes are dependent upon the file size of your digital image.

Sizes

Our exposure unit allows us to print up to 24x36 inches.

Prices

Because our calibrated digital negatives keep us from wasting prints in testing, we are able to pass our savings onto our clients. Our pricing is based on materials costs, your customization requirements, and the market price for platinum and palladium. Because of this we can only provide a basic estimate of pricing on our website. Contact us to discuss your needs or schedule an appointment to visit our lab and samples.

8x10 | $275

11x14 | $375

16x20 | $600

> 16x20 | please inquire

Workshops

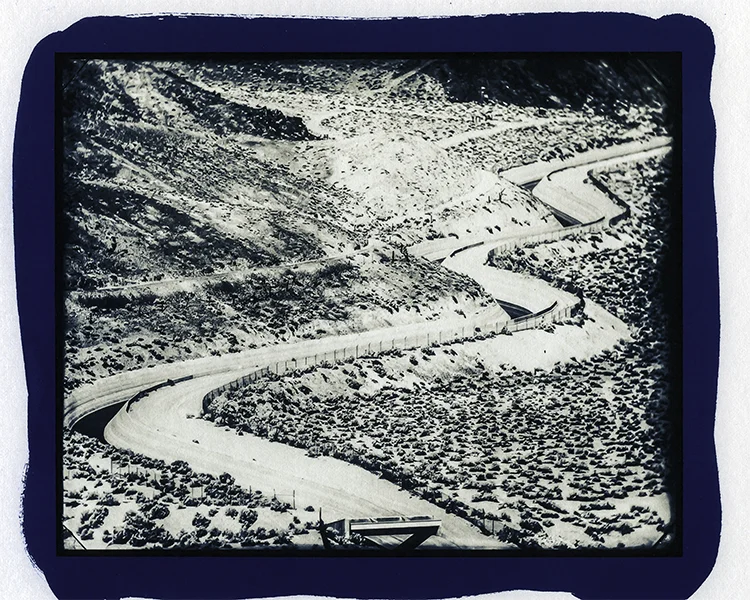

Platinum palladium printing is a 19th century photographic process known for an extended tonal range that results in beautiful transitions from highlights to shadows. It is a classic and timeless aesthetic that is also prized for its archival quality because the noble metals platinum and palladium are used in the light-sensitive chemical solution that is the basis of the image. In this class you will learn the basics of this process combined with 21st century digital imaging which allows us to make handmade platinum palladium prints from your digital photos.

This workshop is for beginners new to platinum palladium as well as those with some experience who want to boost their knowledge of the process or try calibrated digital negatives for the first time. We will walk you through the process—from converting your digital photo to a physical large-format negative (i.e. a digital negative), to mixing your chemical solution of platinum and palladium, to hand-coating paper, to UV exposure, to using different types of developers to produce warm and neutral tones in your final print. Students must bring digital images to make calibrated digital negatives which make platinum palladium printing easier than ever.

We believe in hands-on learning and we will get you started immediately in printing your own images so that you leave the workshop with a strong foundation in the process as well as with multiple prints. It is important to note that platinum and palladium metals are quite expensive which dictates the cost of this workshop.

About the Instructor

David Hyams is an artist and educator with over 2 decades of experience in historical photographic processes and darkroom techniques. He managed the darkroom and designed workshops for Bostick & Sullivan, contributed to research for Christoper James’ “Book of Alternative Processes,” and is a consultant and master printer for a variety of artists. David is the co-founder of Luminaria, an alternative photography studio in Salt Lake City, Utah that offers group and custom workshops, master printing in a wide range of photographic processes, and one-of-a-kind tintype portraiture.

Interested in another type of class? Here are some of our previous offerings. Join our mailing list at the bottom of the page to stay up-to-date on our workshops. Or, schedule and On-Demand Workshop tailored to your needs.